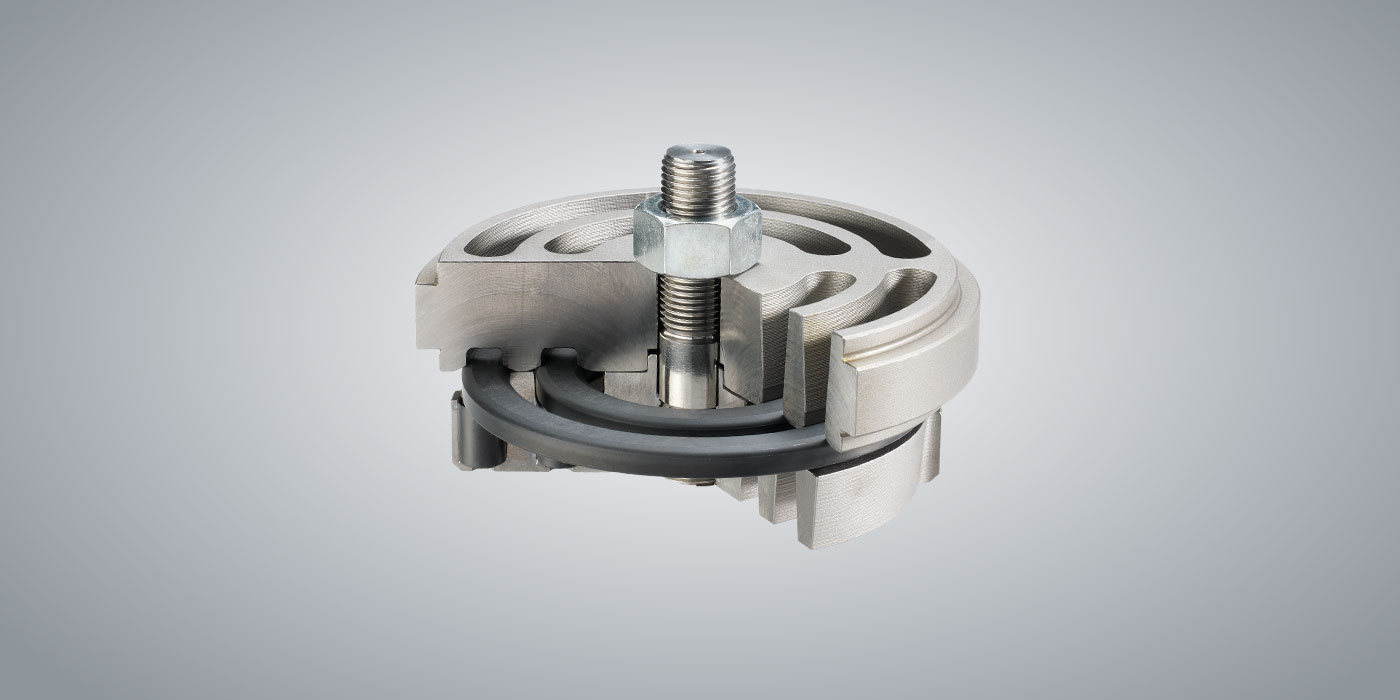

CE – Profiled Ring Valve

Obtain the highest reliability

Quality proven in thousands of applications

The CE Valve has been HOERBIGER’s most popular ring valve for years. Positive experiences from a wide variety of uses attest to the performance of the CE Valve in a broad field of applications. Thanks to its outstanding efficiency, the valve is suitable not only for hydrogen but also for heavy gases such as CO2, carbon monoxide and ethylene.

The HOERBIGER CE Valve is optimally suited for applications in the chemical and process industries, in refineries, and in the energy sector. Successful experience from a large number of field installations proves the performance of the CE Valve in a wide range of applications. The valve offers reliability and efficiency even under difficult conditions.

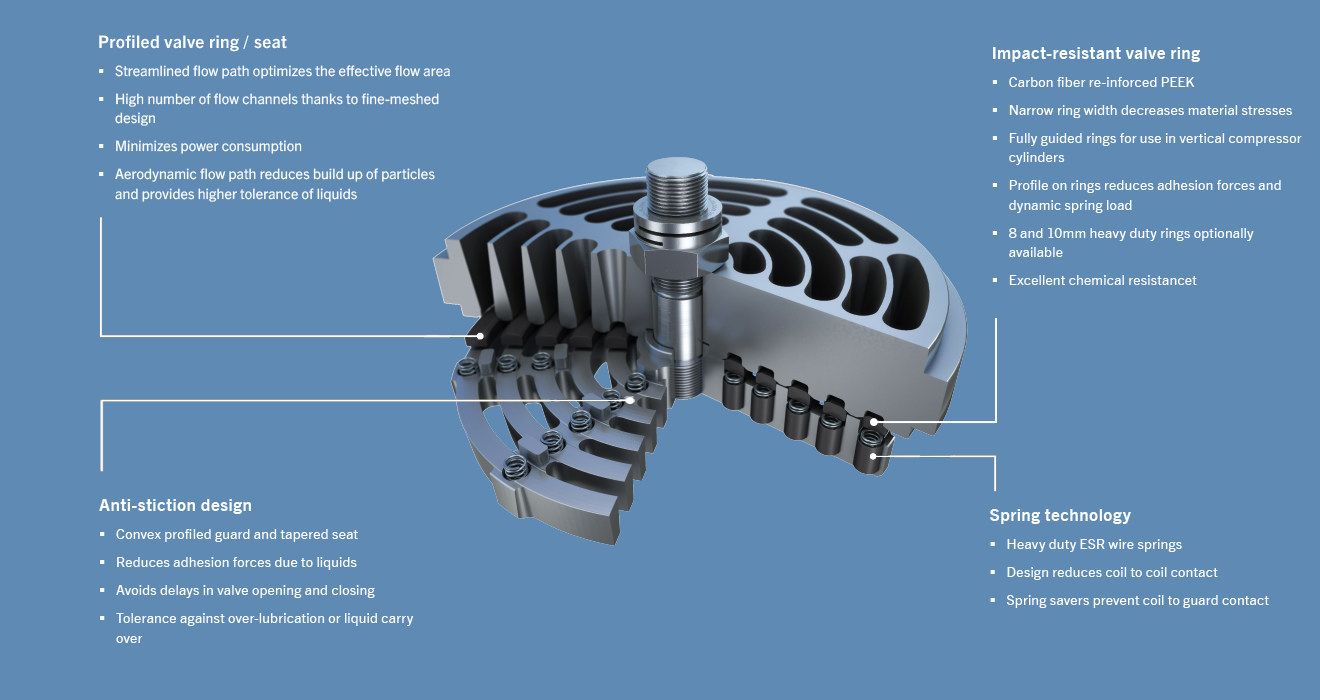

The long service life and high reliability of CE Valves are the result of profiled ring / tapered seat arrangement, impact-resistant valve rings, unique anti-stiction design and the high performance spring technology. This extends maintenance intervals, reduces the risk of premature wear and the associated downtime, and lowers energy consumption.

- High reliability

- High efficiency and long service life

- Low energy consumption

- Safe sealing in wide temperature and pressure range

- Broad application field and high degree of standardization help improve inventory management

- Compressor speed:

- 1200 rpm maximum

- Capacity control:

- On/Off, HydroCOM, eHydroCOM

- Lubrication:

- lube and non-lube

- Maximum pressure:

- 200 bar

- Differential pressure:

- 100 bar

- Temperature range:

- -20°C to 210°C

- Valve type diameter:

- 48 mm (1 ring) - 314 mm (8 rings)

A4

Letter format

CE Valves ensure highest reliability

The CE Valve is highly durable, robust and efficient and provides a proven industry solution that covers a wide range of applications.

Your benefits at a glance

| Feature | Advantage | Benefit | |

|---|---|---|---|

| Profiled ring design | Above industry standard in efficiency: 20 - 40% higher effective flow area than conventional plate or poppet valves |

Long life and high compressor uptime | |

| High number of flow channels | |||

| Spring savers prevent coil-to-guard contact | Tribological optimization | ||

| Carbon fibre reinforced PEEK rings | High flexural strength and impact resistance | ||

| Aerodynamic flow path | Reduces build up of particles and provides tolerance to liquids |

Superior reliability | |

| Fully guided rings | Suitable for vertical compressors | ||

| 8 and 10mm heavy-duty rings | Designed for high dynamic loads (optionally available) | ||

| Anti-stiction design: Convex profiled guard and tapered seat | Reduces adhesion forces due to liquids Avoids delays in valve opening and closing Tolerance against over-lubrication or liquid carryover | ||

| Heavy duty springs made of electro-slag remelting (ESR) steel | Designed for high dynamic loads | ||

| The most efficient ring valve Tribological optimization | Replace wear parts less frequently | Reduce OPEX | |

| Reduce main motor energy costs | |||

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.